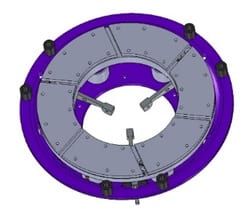

Ace Racing Clutches has a new long-style clutch program available for racing applications. While there is an abundance of 10”, 10.5” and 11” stamped steel cover assemblies on the market, Ace offers a welcomed change from the tradition.

Ace now offers a three-lever version in all three sizes, as well as a six-lever option predominately used on high horsepower applications and in truck/tractor pulling as well. The new Nex-Gen Long is made of 7075 forged aluminum construction and implements several innovative features that bring the assembly into the next generation of the clutch technology.

One of the key design features of the Nex-Gen long style is better heat dissipation with built in cooling fans. By utilizing the forged aluminum cover side profile and cutting CNC machined fins, the new design is able to allow additional heat release with rotation of the engine, which allows for better wear, better consistency and overall ability to perfect the tune up.

In addition to the cooling fans, rotational segmented heat shields have also been added. With the rotation of the grooves, the Nex-Gen encourages better heat release that will work in conjunction to the cooling fins. A segmented heat shield rather than a one-piece heat ring allows for better expansion and contraction through the surface, providing a greater long term flat surface to work with, which increases consistency.

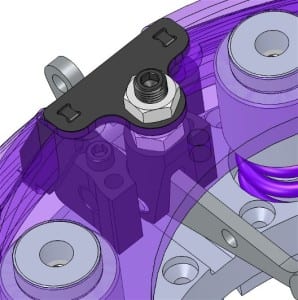

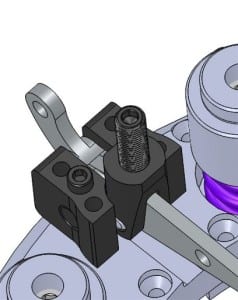

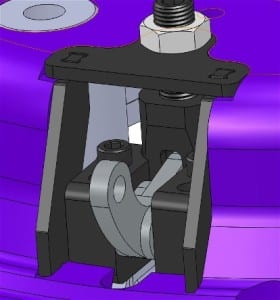

Some of the more exciting new features increase adjustability and tuneability. The Nex-Gen long style will allow you to easily adjust lever height without shimming. This is accomplished with threaded yokes and thrust plates and provide the ability to easily change the lever height on each location while keeping the profile low and accessible. This allows for the counterweight of the clutch to come in more quickly or more slowly depending on the application’s needs. Each clutch assembly will have been dyno tested to provide exact plate load pressures for each additional gram per 100 rpm.

The Nex-Gen long style features hardened stands with guided yokes to help prevent galling issues and breakage. By bolting the lever stands through from the bottom side of the pressure plate, Ace was able to triangulate the drive pressure outward to give greater strength and durability. In addition the lever stands encompass the yokes to allow free guided motion for less resistance and more consistent pressure application. This feature fixes some failure issues of current long style designs.

Thrust and wear pads have also been integrated into the new design to strengthen and provide more durability. This feature works in conjunction to the hardened stands, and is designed into the cover to allow for consistent wear and to allow the aluminum cover to work with the aluminum pressure ring while providing g extreme durability.

The 10-inch version [pictured, right] will start in the $2,100 to $2,200 range for a complete assembly including flywheel, disc and cover. All clutches will have dyno profiling, so customers will be able to tune based on actual centrifugal dyno information for consistency.

Available starting Mid-March 2015. For more information, visit www.aceracingclutches.com

This story was originally published on February 13, 2015.